UP TO THE MINUTE

AI in roofing estimating: A powerful tool — Not a replacement for experience

February 5, 2026 at 6:00 a.m.By Cotney Consulting Group.

AI may change the tools we use, but it doesn’t change what accurate estimating requires. Experience still matters. Professional judgment still matters.

There’s no question that AI is finding its way into roofing. You see it in takeoff software, measurement tools, production planning platforms and even proposal generators. The industry is moving quickly, and 2026 will bring another wave of technology promising speed, accuracy and automation. But let’s be clear: estimating has never been a discipline where you push a button and call it a day. Suppose you’re a contractor who has lived through material swings, labor shortages, jobsite surprises and the pressure of winning profitable work. In that case, you already know that nothing replaces the eyes, judgment and instincts of an experienced estimator.

That’s why AI should be viewed for what it truly is — a powerful tool that can support the estimator, not stand in for them.

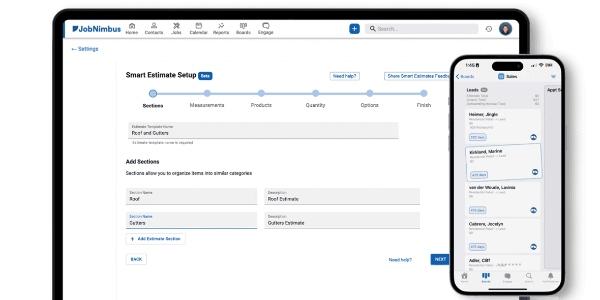

AI shines in places where repetition once slowed us down. Digital takeoff tools now read roof edges, penetrations and slopes faster than a person can zoom and click. Software can organize quantities, label sections and calculate basic production rates. Even document review tools are getting better at flagging unusual specs, warranty requirements and scope notes that might otherwise get missed on a tight deadline. All of this removes time-consuming steps that once kept estimators glued to their screens long after the rest of the office had gone home.

But the leap from speed to accuracy isn’t automatic. AI can count sheets of insulation, but it can’t walk a deck and tell you how soft it feels under your feet. It can highlight details on an architect’s drawing, but it can’t tell you when that detail is unrealistic for a crew working in January on a tight downtown site. It can summarize a spec book, but it doesn’t understand how a change in fastener pattern affects real production or how wind exposure on the east elevation will slow a crew to half its normal pace.

Software may help you build the estimate. Only experience enables you to build the job.

Roofing involves variables that the computer will never fully grasp. Crew mix, travel time, building access, crane limitations, deck condition, weather patterns in your region, the reliability of your supplier, the client’s communication style — none of that is in an algorithm. It lives in the estimator’s head, developed over years of bidding work, walking roofs, talking with supervisors and closing out challenging projects. Those lessons are what protect margins, not the latest update to a takeoff program.

AI also can’t replace what estimators do best: see risk before it becomes cost. A seasoned estimator knows to question a vague transition detail. They know when a spec contradicts itself. They know when to push for clarification, when to allow for flexibility, and when to slow down a salesperson who is going for a fast number without a complete understanding of the scope. Those decisions are the difference between a job that performs and a job that unravels the moment materials arrive.

AI can organize information, but it can’t weigh it.

Where AI truly earns its place is in helping the estimator get more done per hour. The tools reduce busywork and allow estimators to spend their time in the areas that actually require skill — reviewing conditions, modeling labor, assessing risk and pricing the job correctly. This is especially important as the industry continues to lose experienced estimators to retirement and contractors struggle to build bench strength. If used correctly, AI helps newer estimators learn faster by providing cleaner data, better visibility and fewer opportunities to stumble over the basics.

The risk isn’t that AI will replace the estimator. The risk is believing it can.

Contractors who hand the process over to software tend to discover the real problem too late — when change orders pile up, labor blows out the window and the job becomes a drain instead of a winner. Technology can support your estimating department, but it shouldn’t make the judgment calls that decide your margins. You still need someone who understands production and can spot the issues software overlooks.

The future of estimating will be a blend. Contractors who succeed over the next decade will be the ones who embrace the efficiencies of AI while staying anchored in the fundamentals of roofing: knowledge of materials, understanding of crews, clear reading of specifications and the ability to see risk long before it shows up on a cost report.

AI may change the tools we use, but it doesn’t change what accurate estimating requires. Experience still matters. Professional judgment still matters. The best estimators will be the ones who use the new tools well — but never allow the tools to think for them.

Learn more about Cotney Consulting Group in their Coffee Shop Directory or visit www.cotneyconsulting.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In